シボ加工・エンボス加工・プリント配線板

明治38年の創業以来、業界を常にリードし続けてきた技術力で、他社との差別化やオンリーワンの製品作りをお手伝いいたします。

金型事業部

射出成形(インジェクション)、発泡成形、真空成形など、

樹脂成形品のあらゆるお悩みに、解決手段をご提案。- 外観不良、成形不具合対策

- ヒケ、ウェルドライン、フローマーク、

シルバー、

カジリ、白ボケ、白モヤ - 高付加価値化、コスト削減

- 肉厚調整、偏肉対応、軽量化、

離型コーティング - 緊急対応、アフターフォロー

- 出張加工、土日対応、夜間対応、金型修理

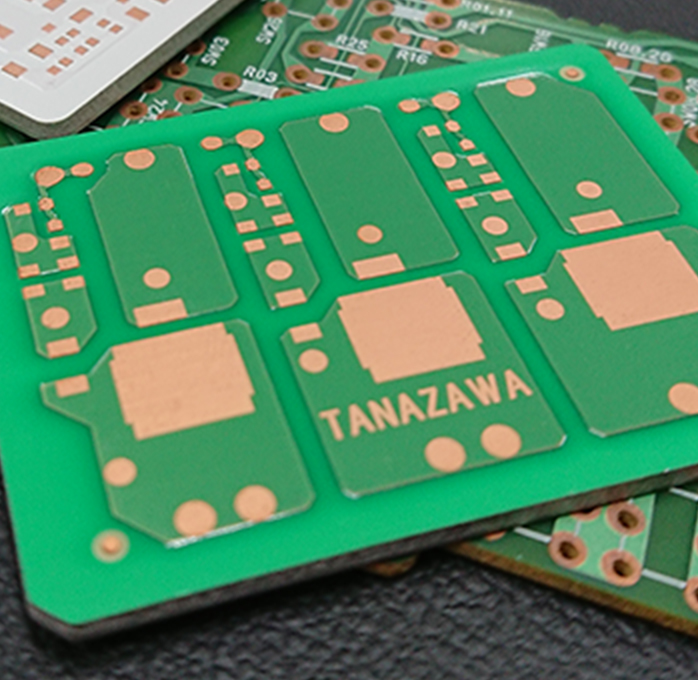

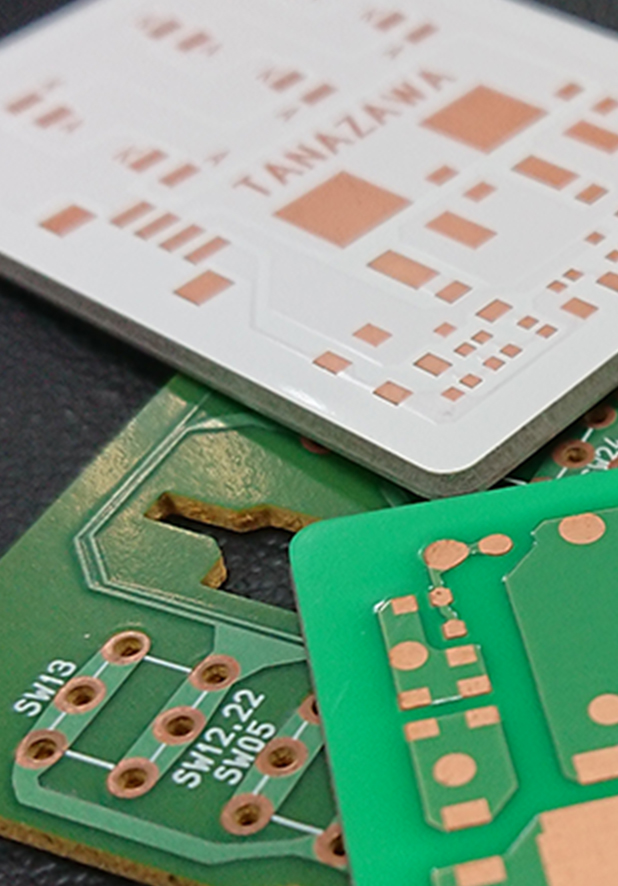

プリント配線事業部

プリント基板のあらゆるお悩みに、

解決手段をご提案。

棚澤八光社の技術力

明治38年の創業以来、業界を常にリードし続けてきた技術力で、他社との差別化やオンリーワンの製品作りをお手伝いいたします。

シボ加工・エンボス加工金型事業部

オーソドックスな皮シボ・梨地・サンドブラスト、未来的なイメージを印象づける幾何学模様、風情を演出する木目・石目などの装飾としてのシボ加工、滑り止めなど製品機能を担うシボ加工、成形不良対策(コスト削減策)としてのシボ加工など、樹脂成形におけるシボの役割は多岐に亘ります。

金型(射出成形用型、バキューム型、ブロー型)、エンボスロ―ルへのシボ加工・エッチング加工で樹脂成形の可能性を拡げます。

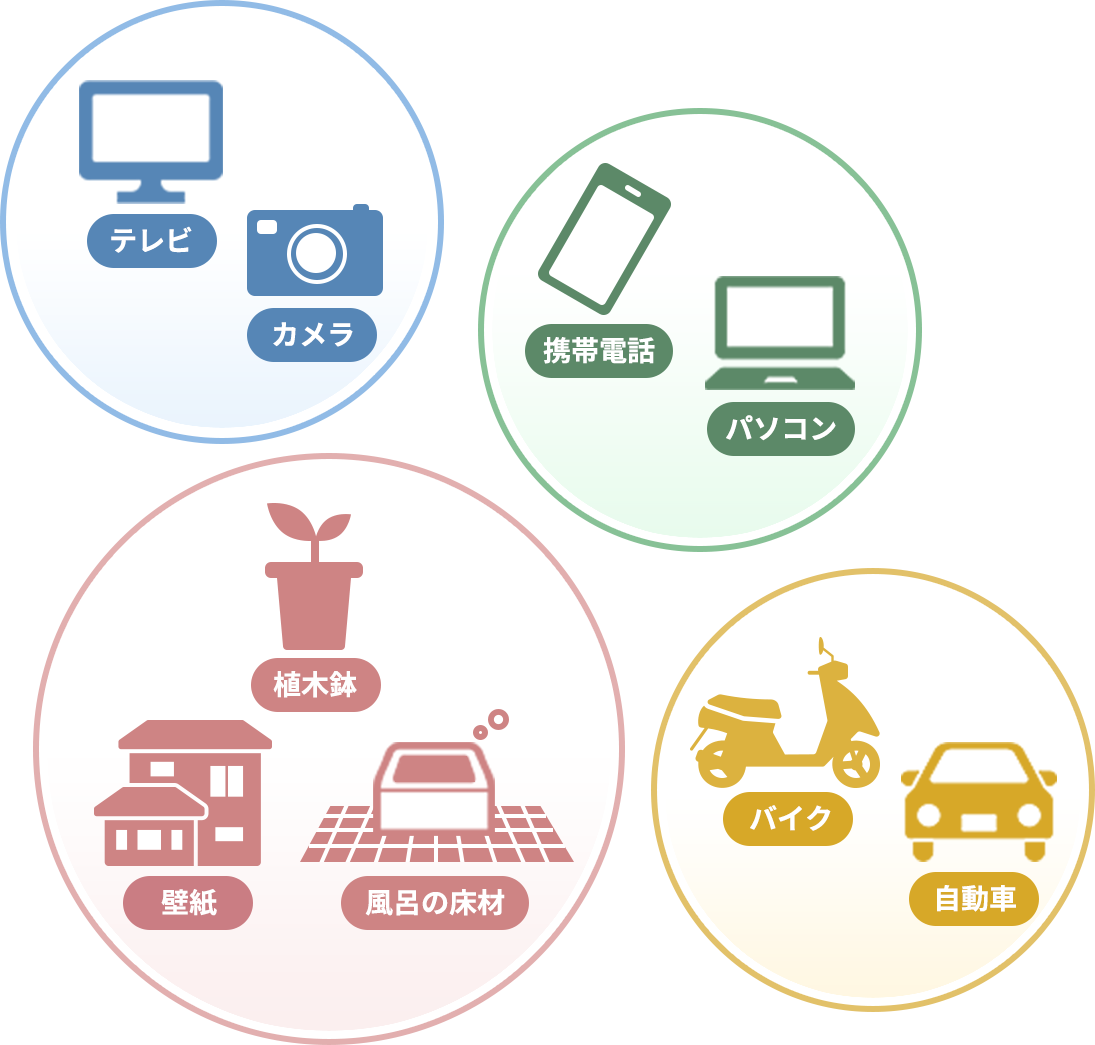

身の回りのシボ加工品

見た目を良くする、手触りを良くするなど、製品付加価値を高める目的で、ありとあらゆるプラスチック製品にシボやエンボスと呼ばれる凹凸模様が加工されています。

自動車の内装(インパネ、ドア、ハンドル)や外装(バンパー、グリル回り)、バイク、テレビやパソコン(キーボード)などの弱電製品、携帯電話、家電、什器(オフィスチェア、)、壁紙、浴室床・壁、雑貨(プラケース、プラ容器)

プリント基板プリント配線事業部

片面基板と両面基板に特化して国内生産しております。特に、片面基板生産量は日本一を誇ります。また、当社営業は、設計から生産までの全工程を熟知。抜群の対応力で、お客様のお困りごとをスピーディに解決致します。

「コストが合わない」「難しい」など他社で断られた案件や「こんなことできますか?」「こんなことしてみたいんだけど…」といった新規案件も、是非当社へご相談ください。

身の回りの片面基板

LED照明(直管タイプ・シーリングライト・ダウンライト・投光器)、車載(ヘッドライト・ルームランプ・コーナーセンサー・ヒーターコントロールパネル)、家電(炊飯器・IHクッキングヒーター・冷蔵庫・洗濯機・エアコン・掃除機・除湿器・ファンヒーター・プリンター)、各種電源部、などに幅広く使用されております。

お知らせ

- 2024.01.08

- ホームページをリニューアルしました

採用に関する

お知らせ

- 2024.02.08

- 採用情報を更新しました